Essential Steps for Pre-Production Quality Assessment in 3D Printing

When ordering 3D printed parts online, ensuring quality before production begins is crucial for project success. The pre-production verification process helps avoid costly mistakes, ensures specifications are met, and delivers the expected results. Understanding how to properly assess and verify part quality before confirming your order can save time, money, and potential headaches down the line.

Modern 3D printing services offer various tools and methods to verify part quality before production. From digital analysis tools to material verification systems, these pre-production checks have become increasingly sophisticated. Let's explore the comprehensive approaches to ensure your 3D printed parts meet quality standards before hitting the print button.

Digital Design Verification Tools

Automated File Analysis Systems

Digital design verification begins with automated file analysis systems that examine your 3D model for potential issues. These sophisticated tools scan for common problems like wall thickness violations, mesh errors, and structural weaknesses. The analysis provides detailed reports highlighting areas that might cause printing failures or compromise part quality.

Modern 3D printing platforms integrate advanced algorithms that can detect and even automatically repair minor mesh issues. These systems evaluate the model's printability across different materials and processes, ensuring the design meets manufacturing requirements before production begins.

Visual Preview and Orientation Tools

Advanced visualization tools allow customers to examine their parts from every angle before production. These tools provide accurate representations of how the final product will look, including surface finish, layer lines, and support structure locations. Users can rotate, zoom, and analyze different sections of their model to ensure every feature meets their expectations.

Part orientation preview tools help understand how the printing direction affects quality and strength. This visualization helps identify potential weak points and optimize the part's positioning for the best possible outcome. Many platforms now offer real-time feedback on how orientation changes impact print quality and cost.

Material and Process Validation

Material Property Verification

Before confirming an order, understanding the material properties is essential for quality assurance. Leading 3D printing services provide detailed material datasheets, mechanical properties, and environmental resistance information. This data helps verify if the chosen material meets the functional requirements of your application.

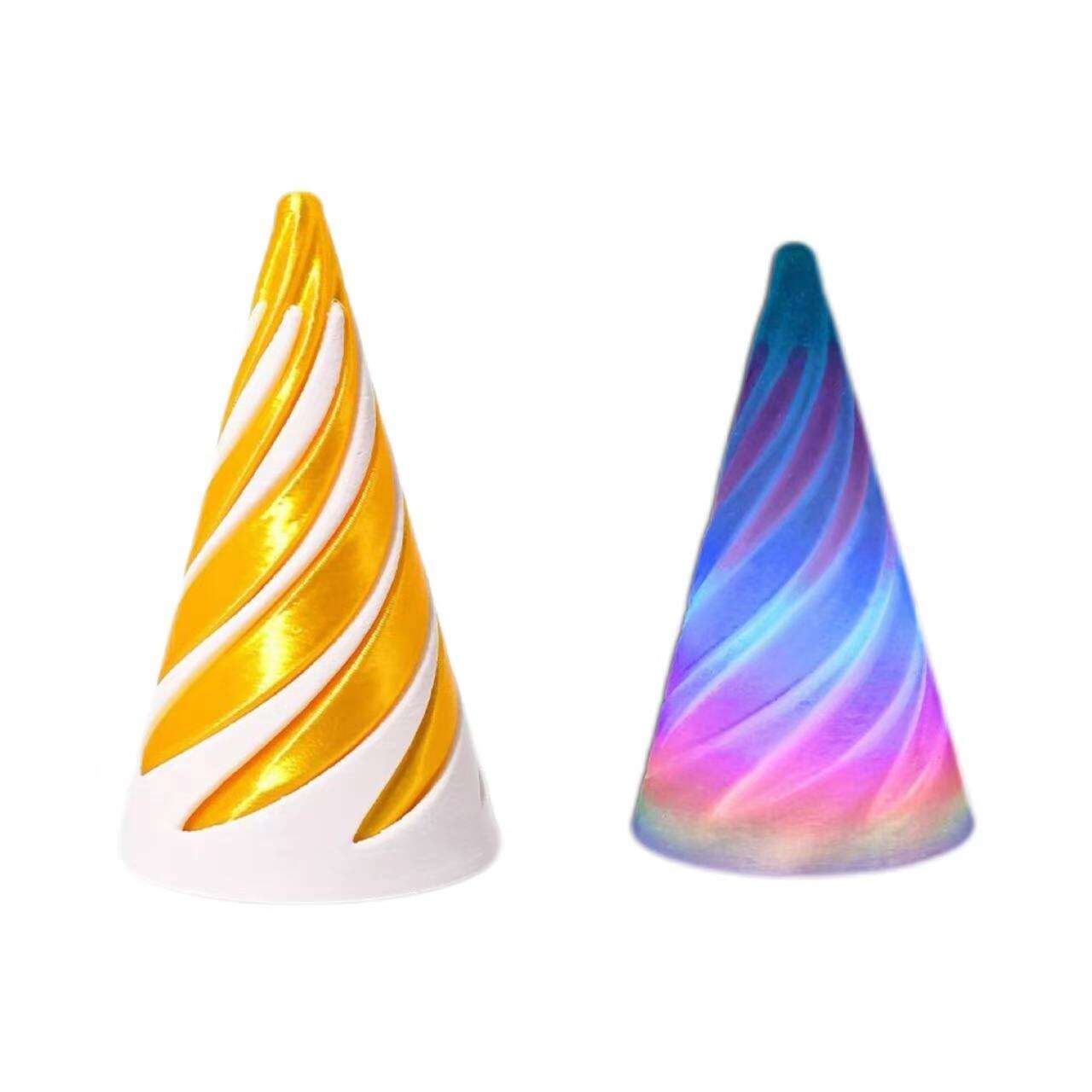

Many platforms now offer material sample kits or test specimens that demonstrate various properties like surface finish, color accuracy, and mechanical characteristics. These physical examples provide tangible evidence of what to expect from the final product.

Process Parameter Assessment

Different 3D printing processes have unique parameters that affect part quality. Understanding and validating these parameters ensures the final product meets specifications. Modern platforms provide detailed information about layer heights, support structures, and post-processing options that influence the final result.

Some services offer process simulation tools that show how different parameters affect the printing process. These simulations can predict potential issues like warping, shrinkage, or support interference before production begins.

Quality Assurance Standards and Certifications

Manufacturing Standards Compliance

Professional 3D printing services adhere to established manufacturing standards and quality control protocols. Before ordering, verify the service provider's certifications and quality management systems. This information indicates their commitment to consistent quality and reliability.

Look for providers that follow ISO standards and maintain documented quality control procedures. These certifications ensure systematic approaches to quality management and continuous improvement in their manufacturing processes.

Quality Control Documentation

Request and review quality control documentation before confirming your order. This may include inspection reports, material certificates, and process validation documents. Understanding the quality control measures helps ensure your parts will meet specifications.

Many services now provide digital quality assurance certificates with each order, documenting the inspection results and confirming compliance with specified requirements.

Pre-Production Communication and Support

Technical Consultation Services

Engaging with technical support teams before production helps clarify requirements and identify potential issues. Professional 3D printing services offer consultation to review design features, material selection, and quality expectations.

Take advantage of these expert resources to discuss specific quality concerns and get recommendations for optimizing your design. This proactive approach helps prevent quality issues before they occur.

Design Review Sessions

Scheduled design review sessions with manufacturing experts provide valuable insights into part quality optimization. These sessions can identify potential improvements in design, material choice, or manufacturing approach.

During these reviews, experienced engineers can suggest modifications that enhance printability while maintaining design intent. This collaborative approach ensures the best possible outcome for your project.

Frequently Asked Questions

What file formats provide the best quality assurance for 3D printing?

STL and 3MF formats are industry standards that provide reliable quality assurance. These formats maintain design integrity and include important manufacturing information. For complex parts, native CAD files or STEP formats may offer additional quality verification capabilities.

How can I ensure dimensional accuracy before production?

Utilize the platform's digital measurement tools to verify critical dimensions. Request tolerance specifications for your chosen process and material. Many services offer dimensional accuracy guarantees and can provide pre-production inspection reports for critical features.

What quality indicators should I look for in a 3D printing service provider?

Look for ISO certifications, documented quality control procedures, and comprehensive material testing capabilities. Check their track record with similar projects, available case studies, and customer reviews. The provider should offer clear communication channels and technical support throughout the order process.