CNC turning is a highly automated mechanical machining technology that precisely controls the motion path of a lathe through computer programming, enabling high-precision machining of metallic or non-metallic materials. Our CNC turning services are widely applied across various manufacturing sectors, including aerospace, automotive manufacturing, medical devices, electronic communications, robotics, and more.

What is CNC Turning?

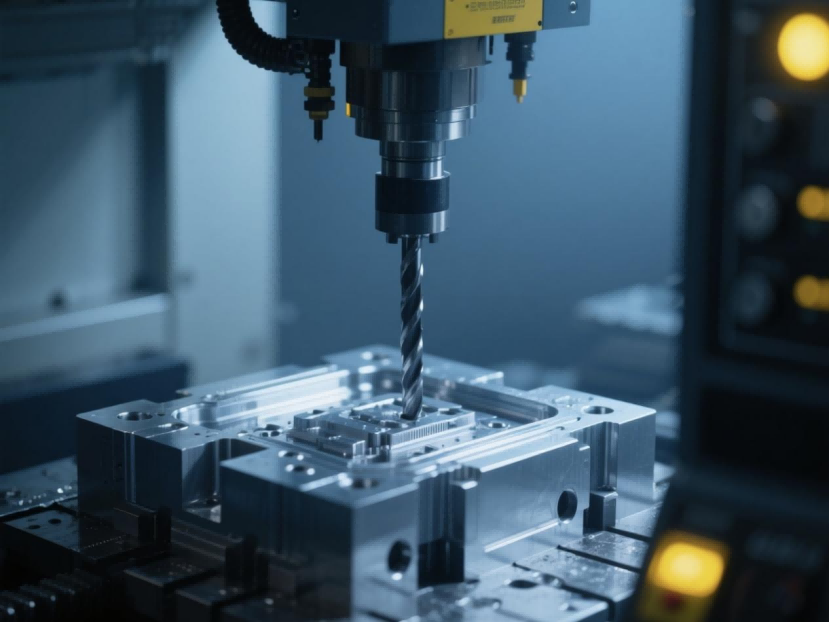

CNC Turning refers to a highly automated mechanical machining process that utilizes computer numerical control (CNC) technology to precisely control the movement of a lathe. In this process, a cutting tool is used to remove material from a rotating workpiece (usually a metal or non-metallic bar or rod) to create a desired shape or feature. The CNC system interprets digital design files and guides the lathe's movements accordingly, ensuring high precision and repeatability in the manufacturing process. |

|

Key Features of CNC Turning Service

| High-Precision Machining | CNC turning can achieve micron-level machining accuracy, meeting the manufacturing needs of high-precision components. |

| Efficient Production | The automated machining process significantly enhances production efficiency and shortens delivery lead times. |

| Versatility | Capable of machining components with various complex shapes and sizes, catering to the personalized needs of different customers. |

| Wide Material Adaptability | Supports the machining of a variety of metallic and non-metallic materials, broadening the range of applications. |

In summary, our CNC turning service provides high-quality, customized components that meet the most stringent specifications. Whether you require prototype development, small-batch production, or large-scale manufacturing, our CNC turning capabilities ensure precision, efficiency, and reliability at every step.