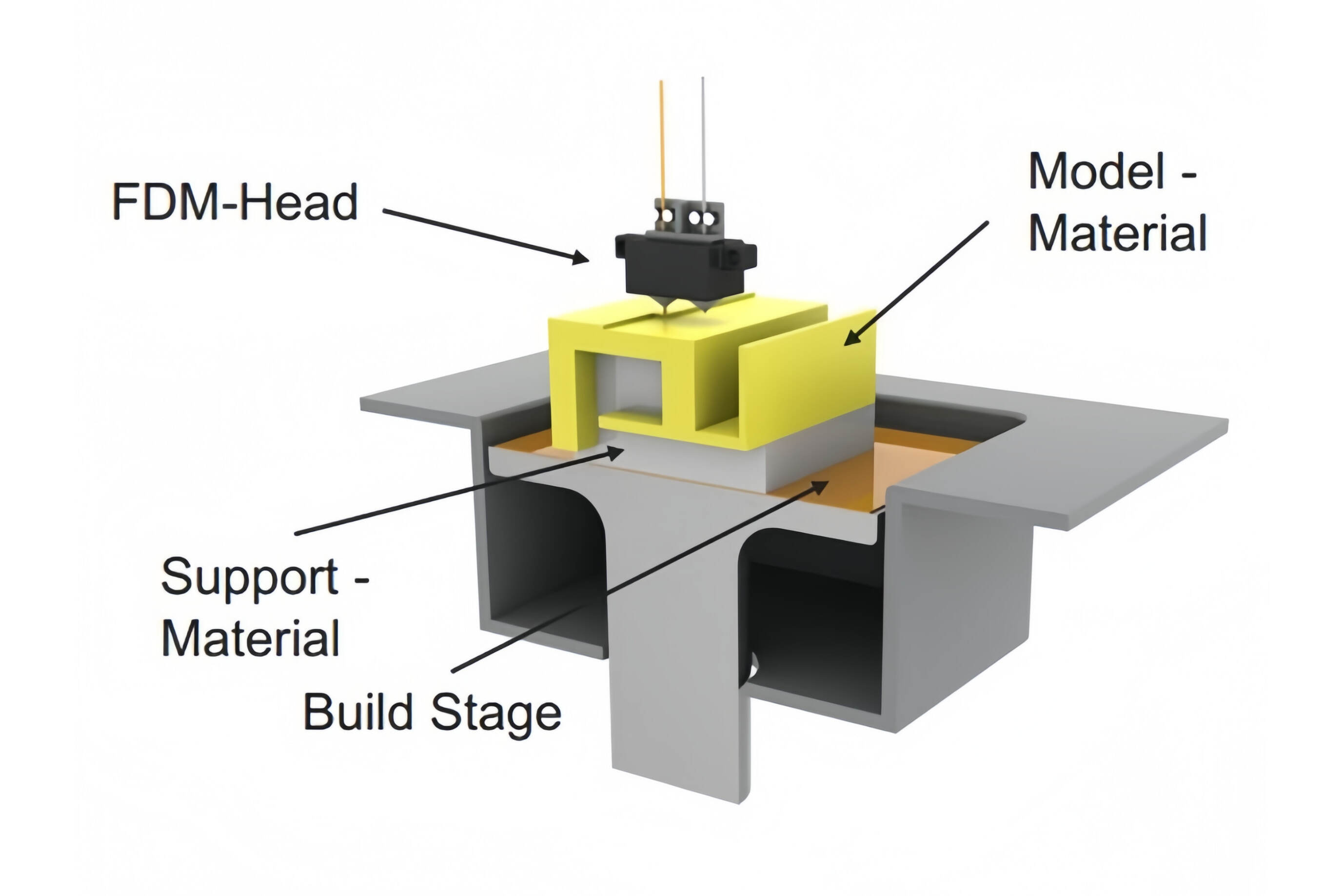

Fused Deposition Modeling (FDM) is a popular 3D printing process that extrudes molten thermoplastic material through a heated nozzle, layer by layer, to build up a three-dimensional object. This technology is highly adaptable, allowing for the use of various filament materials with different properties, such as PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), and more. FDM is ideal for creating functional prototypes, educational models, and end-use parts where cost-effectiveness and material diversity are priorities.

| Material | Color | Tensile Strength(XY) |

Young's Modulus(XY) |

Elongation at break(XY) |

Density g/cm3 |

| PLA Basic | Available in a variety of colors | 35±4 Mpa | 2580±220 Mpa | 12.2±1.8 % | 1.24 g/cm3 |

| ABS | Available in a variety of colors | 33±3 Mpa | 2200±190 Mpa | 10.5±1.0 % | 1.05 g/cm3 |

| PETG | Available in a variety of colors | 32±4 Mpa | 1460±190 Mpa | 11.2±0.8 % | 1.25 g/cm3 |

| TPU 95A HF | Available in a variety of colors | 27.3±0.8 Mpa | 9.8±0.7 Mpa | 650% | 1.22 g/cm3 |

| TPU 85A | Available in a variety of colors | 12.0±0.8 Mpa | 6.8±0.7 Mpa | 700% | 1.18 g/cm3 |

| TPU 90A | Available in a variety of colors | 12.5±0.8 Mpa | 5.3±0.7 Mpa | 650% | 1.24 g/cm3 |

| ASA | Available in a variety of colors | 37.0±3 Mpa | 2450±270 Mpa | 9.2±1.4 % | 1.05 g/cm3 |

The FDM 3D printing process begins with thermoplastic filament being fed into a heated extruder. The filament melts within the extruder and is then extruded through a fine nozzle onto a build platform. The nozzle moves according to a computer-generated path, depositing the molten material layer by layer. As each layer cools and solidifies, it adheres to the layer below, gradually building up the three-dimensional object. Once printing is complete, the part is removed from the build platform and may undergo post-processing steps such as sanding, painting, or assembly to achieve the desired finish and functionality. |

|

|

Advantages

|

Drawbacks

|