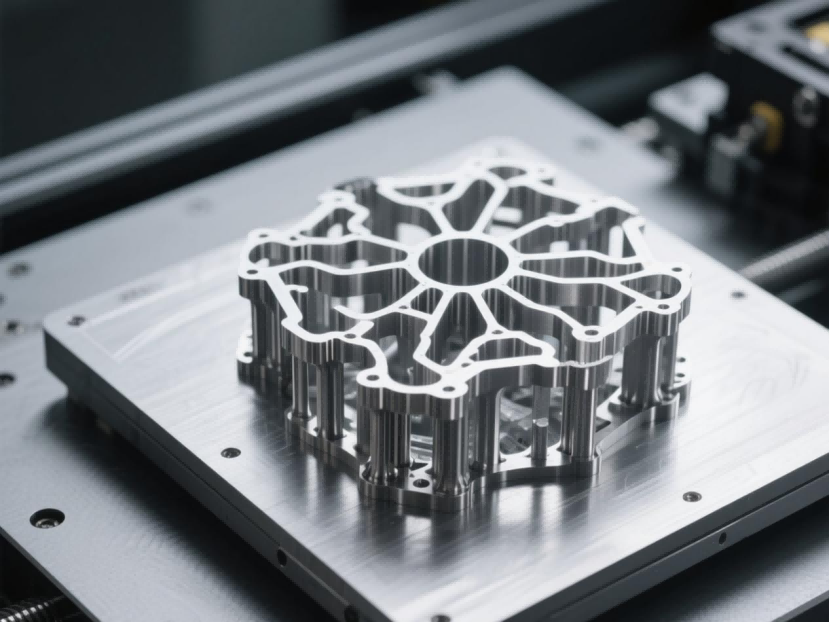

Multi Jet Fusion (MJF) is an advanced 3D printing technology known for its ability to produce high-quality, functional parts with excellent mechanical properties and surface finish. Unlike traditional 3D printing methods, MJF utilizes a combination of inkjet arrays and heating elements to selectively fuse powdered materials layer by layer. This process results in parts with uniform density, high strength, and good dimensional accuracy, making it suitable for a wide range of applications across industries such as automotive, aerospace, and consumer goods.

| Material | Color | Tensile Strength(XY) |

Tensile Modulus(XY) |

Elongation at break(XY) |

Density |

| PA12 | Black | 48 Mpa | 1700 Mpa | 20% | 1.01g/cm3 |

The MJF 3D printing process begins by spreading a thin layer of powdered material across the build platform. Inkjet arrays then apply a fusing agent and detailing agent to specific areas of the powder layer, guided by a precise computer-controlled system. A heating element passes over the layer, causing the fusing agent to activate and bond the powder particles together. The build platform then lowers slightly, and a new layer of powder is spread and fused, repeating the process until the entire part is complete. After printing, the part is carefully removed from the powder bed, and any excess powder is removed through a cleaning process. |

|

|

Advantages

|

Drawbacks

|