Stereolithography (SLA) is a cutting-edge 3D printing technology renowned for its ability to produce highly detailed, smooth-surfaced parts with exceptional accuracy. It utilizes a laser to selectively cure liquid photopolymer resin layer by layer, enabling the creation of complex geometries and fine features that are difficult to achieve with other printing methods. Our SLA service offers a variety of resin materials, each with unique properties tailored to specific applications, such as high transparency, flexibility, or heat resistance. Choose our SLA service for a 3working day standard delivery, ensuring you receive high-quality prototypes and production-ready parts with precision and speed.

| Material | Color | Tensile Strength(XY) |

Tensile Modulus(XY) |

Elongation at break(XY) |

Density |

| 9400 | White | 38-56Mpa | 2559-2678Mpa | 8-14% | 1.11-1.15 g/cm3 |

| LAST-A | Yellow-green | 41-58Mpa | 2649-2731Mpa | 8-12% | 1.11-1.15 g/cm3 |

| TOP318 | Black-gray | 41-58Mpa | 2649-2731Mpa | 7-11% | 1.11-1.15 g/cm3 |

| CRYSTA-A7 | Clear | 44-62Mpa | 2490-2617Mpa | 7-11% | 1.12 g/cm3 |

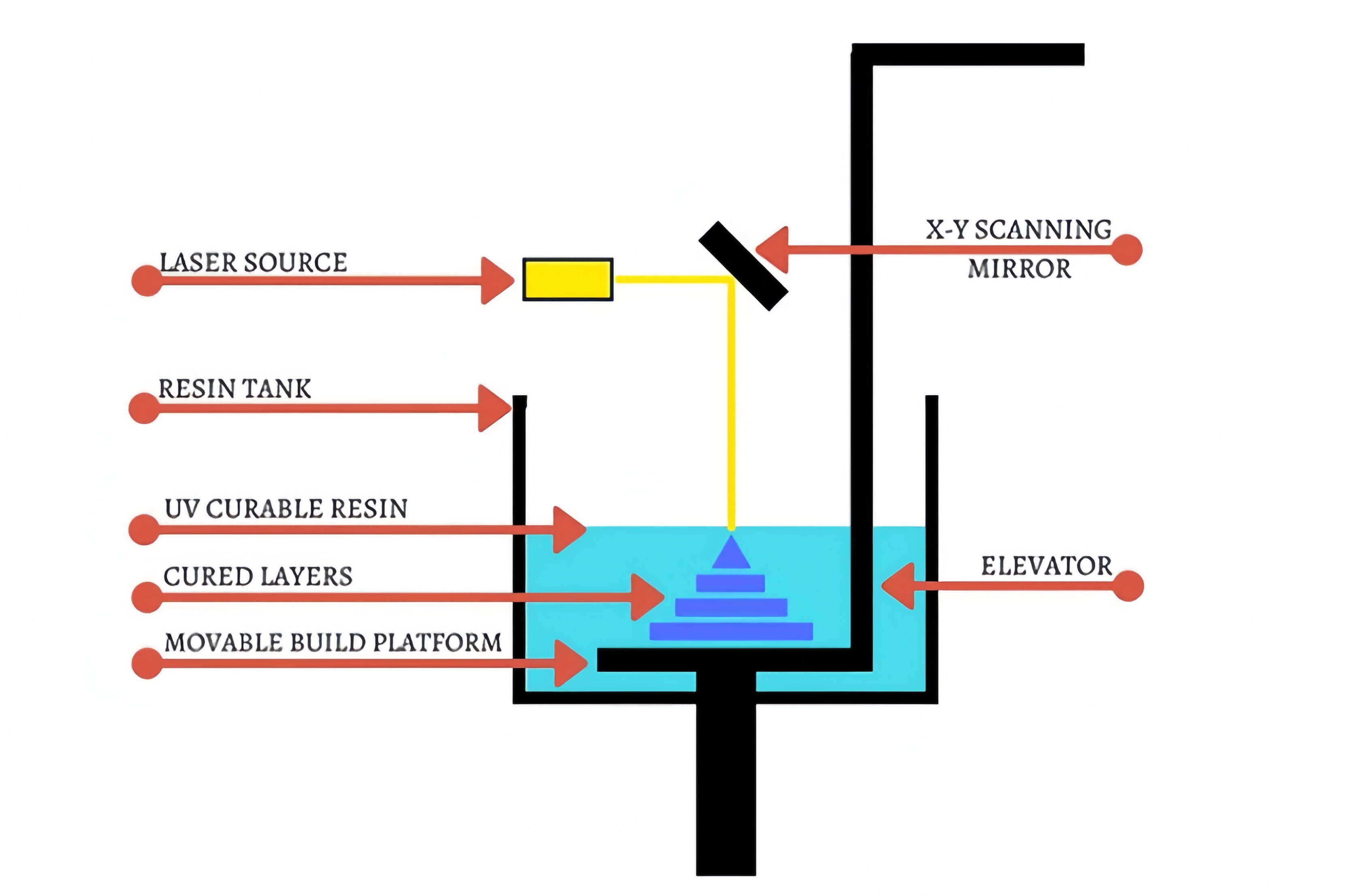

The SLA (Stereolithography) 3D printing process begins in a print tank or container filled with liquid photopolymer resin. Guided by a precise computer-controlled system, a laser beam traces the cross-sectional shape of the part to be printed on the surface of the resin, solidifying it layer by layer. After each layer of resin is cured, the build platform lowers slightly according to the preset layer thickness parameters, and a new layer of liquid resin is evenly spread over the previously cured layer. This process repeats until the entire part is fully printed. Once printing is complete, the part is carefully removed from the print tank. First, the support structures are removed, followed by ultrasonic cleaning to thoroughly eliminate any residual resin material on the part's surface. Finally, the part is placed under ultraviolet light for further curing, significantly enhancing its mechanical properties and long-term stability. |

|

|

Advantages

|

Drawbacks

|