Formlabs LFD technology is an advanced form of stereolithography (SLA) 3D printing designed to produce parts with exceptional detail, accuracy, and surface quality. Unlike traditional SLA, which uses a high-powered laser to cure resin, LFD employs a lower-force approach, resulting in reduced stress on the printed part and enabling the creation of more intricate and delicate geometries. This technology is particularly well-suited for applications that demand high fidelity and a polished appearance.

| Material | Color | Tensile Strength(XY) |

Tensile Modulus(XY) |

Elongation at break(XY) |

| Tough 1500 | Gray-black | 33MPa | 1.5GPa | 51% |

| Tough 2000 | Off-white | 46MPa | 2.2GPa | 48% |

| Rigid 4000 Resin | White | 69MPa | 4.1GPa | 5.30% |

| Flexible 80A | Clear | 8.9 Mpa | N/D | 120% |

| Elastic 50A | Clear | 3.23 Mpa | N/D | 160% |

| High Temp | Black | 58MPa | 2.8 Gpa | 2.30% |

| ESD | Black | 44.2Mpa | 1.937Gpa | 12% |

| Silicone 40A | Black | 5Mpa | N/D | 230% |

| Flame Retardant Resin | Gray | 41Mpa | 3.1Gpa | 7.10% |

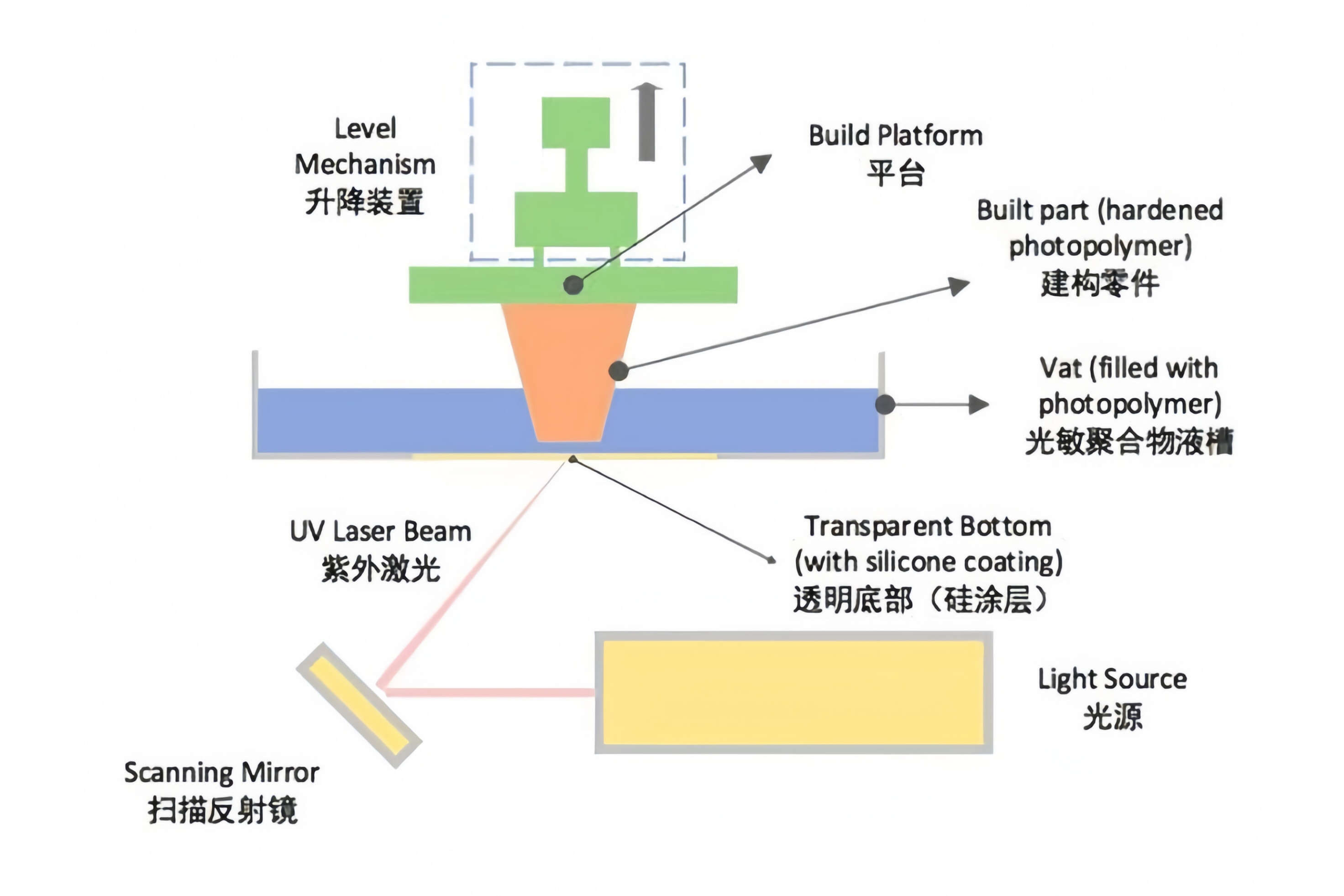

The Formlabs LFD 3D printing process begins by filling a print tank with a liquid photopolymer resin. A low-force laser, guided by a precise computer-controlled system, traces the cross-sectional shape of the part to be printed on the surface of the resin, selectively curing it layer by layer. Unlike traditional SLA, the lower laser power reduces the internal stresses within the part, minimizing the risk of warping or cracking. After each layer is cured, the build platform lowers slightly, and a new layer of resin is evenly spread over the previously cured layer. This process repeats until the entire part is fully printed. Once printing is complete, the part is carefully removed from the print tank, support structures are removed, and the part undergoes ultrasonic cleaning to eliminate any residual resin. Finally, the part is placed under ultraviolet light for further curing, enhancing its mechanical properties and stability. |

|

|

Advantages

|

Drawbacks

|