Direct Metal Laser Sintering (DMLS) is an advanced 3D printing technology designed for the fabrication of metal parts with exceptional mechanical properties and intricate geometries. It utilizes a high-powered laser to selectively melt and fuse metal powder particles layer by layer, enabling the creation of dense, high-strength metal components that are difficult or impossible to produce using traditional manufacturing methods. Our DMLS service offers a range of metal materials, including stainless steel, titanium, aluminum, and cobalt chrome, each with unique properties tailored to specific applications. Choose our DMLS service for rapid prototyping and production of metal parts with precision, speed, and material diversity.

| Material | Tensile Strength(XY) |

Yeild Strength(XY) |

Elongation at break(XY) |

Density | Hardness |

| AISI10Mg | 460±30 Mpa | 270±30 Mpa | 9±2 % | 2.7 g/cm3 | 70±3HRB |

| TC4 | 1200±50 Mpa | 1100±50 Mpa | 10±2 % | 4.4 g/cm3 | 36±4HRC |

| 316L | 670±50 Mpa | 530±60 Mpa | 50±10 % | 7.9 g/cm3 | 34±3HRC |

| 18Ni300 | 1150±50 Mpa | 1100±50 Mpa | 18±3 % | 8.1 g/cm3 | 36±4HRC |

| IN718 | 1060±50 Mpa | 780±50 Mpa | 27±5 % | 8.2 g/cm3 | 74±4HRB |

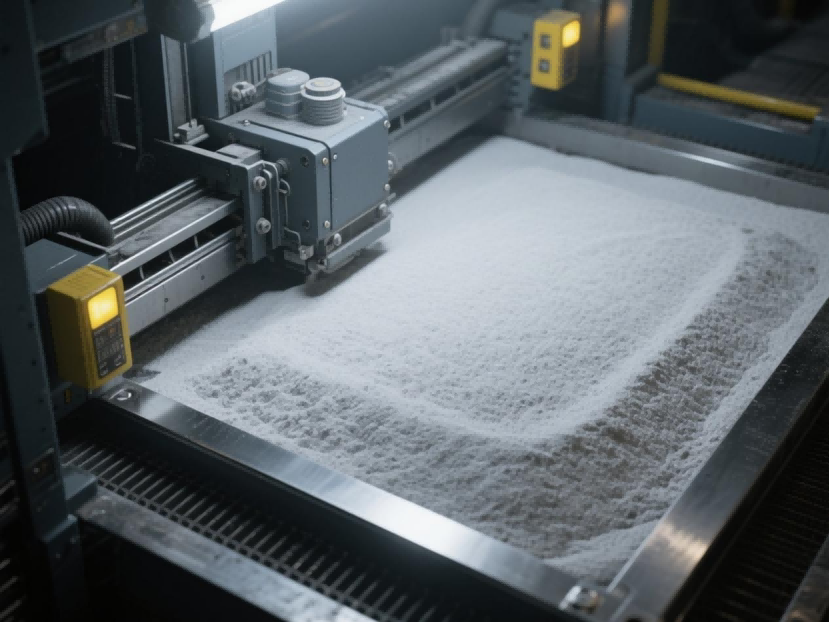

The DMLS 3D printing process begins in a build chamber filled with a fine layer of metal powder. A high-powered laser beam, guided by a precise computer-controlled system, traces the cross-sectional shape of the part to be printed on the surface of the powder bed, selectively melting and fusing the metal particles together. After each layer is sintered, the build platform lowers slightly, and a new layer of metal powder is spread evenly over the previously sintered layer. This process repeats until the entire part is fully printed. Once printing is complete, the part is carefully removed from the build chamber, and any excess powder is removed. The part may undergo post-processing steps such as heat treatment, surface finishing, and machining to achieve the desired mechanical properties and surface finish. |

|

|

Advantages

|

Drawbacks

|